How MERV Choices Impact Energy, IAQ, and Total Cost of Ownership

A practical guide for facility managers to select the right MERV rating, protect airflow, and lower lifecycle costs.

Your filter’s MERV rating directly affects indoor air quality (IAQ), fan energy, and service life. Higher isn’t always better—especially if system static pressure or fan capacity is tight. Use this guide to balance cleanliness, efficiency, and total cost of ownership (TCO).

MERV Basics (What It Measures)

- MERV 8: General dust and lint—cost-effective system protection.

- MERV 11: Finer dust, dander, and mold spores—better IAQ without large airflow penalties in most systems.

- MERV 13: Small particles including smoke and some bacteria—higher IAQ targets in offices, education, and healthcare spaces.

Key point: Always confirm your unit’s allowable pressure drop and fan curve before stepping up MERV.

MERV vs. IAQ vs. Energy: Quick Comparison

| MERV | IAQ Improvement | Typical Use | Energy Impact* | Change Interval** |

|---|---|---|---|---|

| 8 | Basic particle reduction | General commercial, residential | Low | 3–4 months |

| 11 | Enhanced allergen capture | Schools, offices, mixed-use | Low–Moderate | 2–3 months |

| 13 | High-efficiency fine particle capture | Healthcare, high-IAQ programs | Moderate (verify fan capacity) | 1–3 months |

*Energy impact varies with pressure drop, duty cycle, and fan control. **Intervals depend on load and hours.

Optimizing Total Cost of Ownership (TCO)

- Right-size the rating: Choose the lowest MERV that meets IAQ goals and system specs.

- Watch pressure drop: As filters load, static rises. Use differential pressure readings where possible.

- Extend life via capacity: Extended-surface pleats often hold more dust, reducing change frequency.

- Standardize SKUs: A simplified set of sizes/MERVs lowers inventory and ordering overhead.

- Order by the case: Improve unit cost and ensure availability during peak seasons.

5 Signs It’s Time to Replace Filters

- Rising differential pressure approaching your change-out setpoint.

- Reduced airflow or comfort complaints in serviced zones.

- Visible dust accumulation downstream of the filter rack.

- Fan motors drawing higher current than baseline.

- Filters at or beyond the scheduled interval under heavy loads.

Build a Simple Replacement Program

- Create a site inventory (sizes, counts per change, MERV, locations).

- Set intervals by environment: 1–2 months (heavy load), 2–3 months (typical), 3–4 months (light use).

- Label cases by unit/area; stage stock near service routes.

- Align changes with seasonal PM to reduce truck rolls.

- Track usage to refine budgets and schedules each quarter.

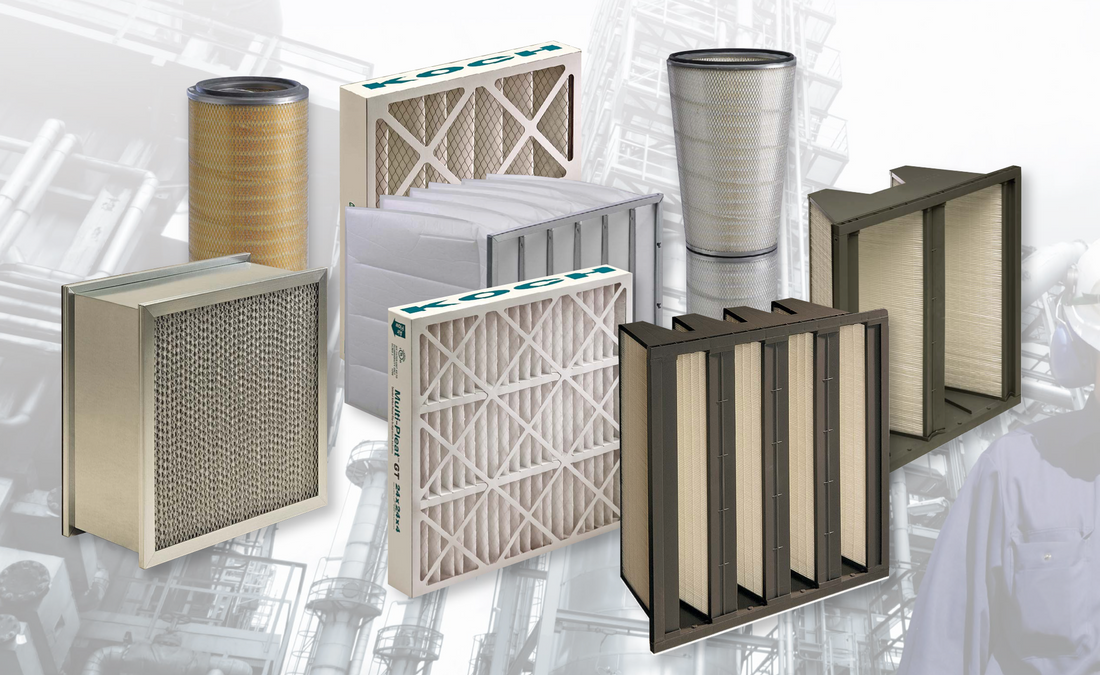

Your Partner for Efficient Filtration

HVAC Filter Solutions helps facilities choose the right MERV, standardize SKUs, and set smart intervals—so airflow stays on target and lifecycle costs go down.

Need help selecting MERV ratings or planning stock? Our team can build a filter plan tailored to your buildings and budget.